In today’s design world, accuracy is more than just a nice to have thing, it’s something you need. Whether it’s a robotic arm doing micro assembly, aerospace parts under pressure or industrial equipment with an application for strain measurement – knowing the force being applied could make or break performance. Force sensors are there to help.

They are small but mighty pieces of equipment, quietly performing endless tasks done by automation robots or test systems. But how do they work? What are the types of force sensors? But why do engineers/scientists/industries care about the force sensor working?

Here’s a detailed look at what they are, how they work and where they make the biggest difference.

What Are Force Sensors?

Ok so before we get into all of that let’s ease in shall we? What are force sensors?

What is a force sensor? In simplest terms, a force sensor is something that measures the force applied to an object. That force can be tension (pulling), compression (pushing), torque (twisting), and sometimes shear (sliding).

Force transducers convert mechanical force into a signal that can be measured and processed by an external device. This conversion is what makes systems used by robots, cars and testing machines able to “feel” and respond to the amount of force applied.

Consider an industrial robot arm piecing together fragile glass part. If there were no force sensor to inform the robot when it should stop pressing, it would probably shatter the glass. But with sensors, it can actually measure pressure in real time and adjust its grip accordingly.

That is the real-world significance of force sensors, providing machines with a sense of “touch.”

The Force Sensor Working Principle

Now that you know their types, let’s discuss the working of force sensors.

All force sensors are based on the same principle: a conversion of mechanical energy (force) into an electric signal. But the manner of this conversion depends on what sensor technology is used.

Here’s how it works step-by-step:

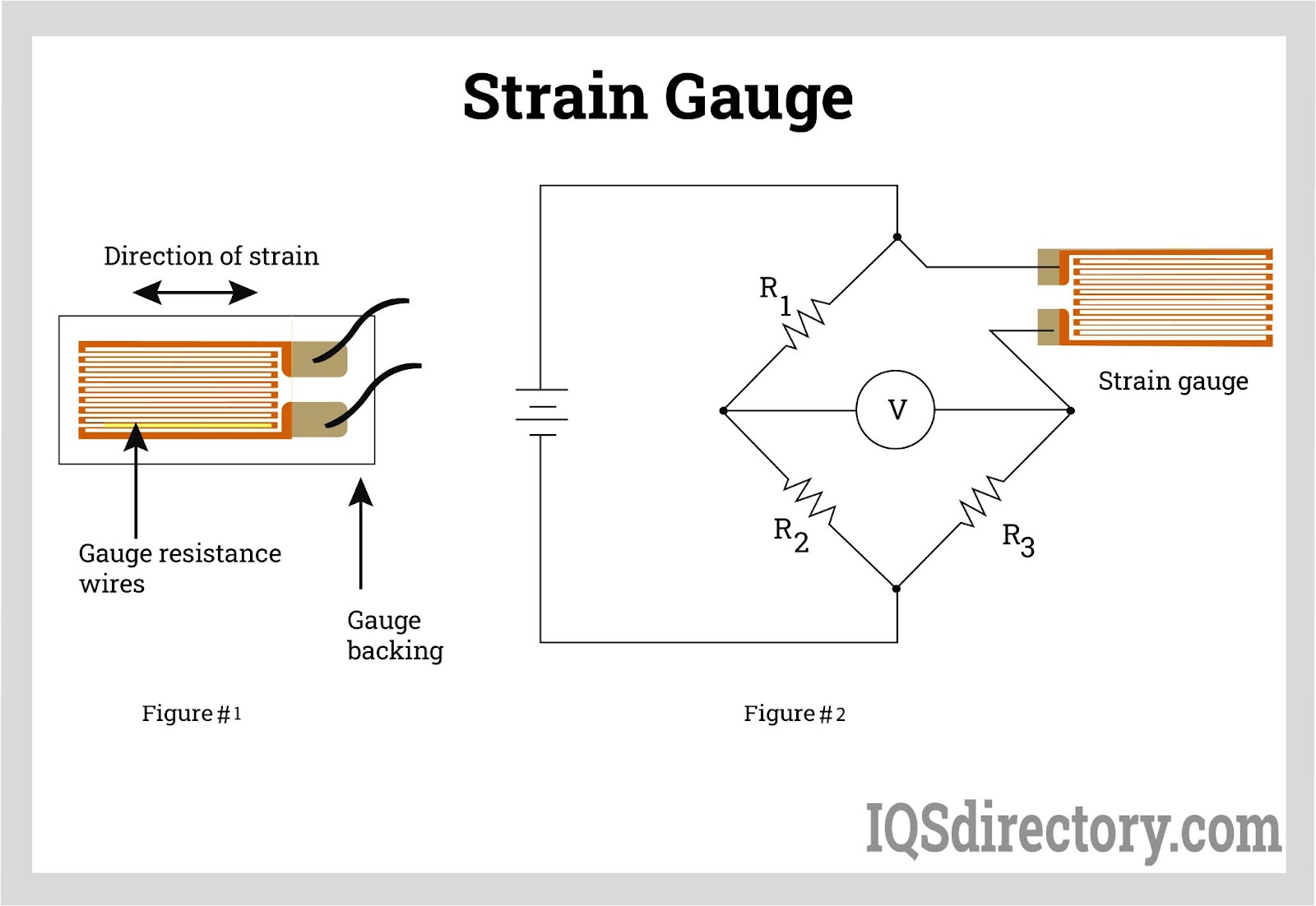

- Force Application – An external force (pushing, pulling or twisting) exerted on the sensor results in a physical change within the structure of the sensor, like deformation or strain.

- Sensing Element Response – The sensor element, i.e. a strain gauge, piezoelectric crystal or capacitive plate, to which the object is attached deforms in response.

- Signal Conversion – This variation is converted to an electrical signal, such as a change in voltage, resistance or current.

- Amplification and Output of the Signal – The raw signal is amplified and conditioned before it is fed to a controller or data system for processing.

In layperson’s terms, when you push on a force sensor, it turns that pressure into ambiguous numbers, a kind of “digital fingerprints” of force.

Main Types of Force Sensors

Although all force sensors have the same function, they are based on different technologies. The following are some of the main types of force sensors in use by industries today.

- Strain Gauge Force Sensors: These are the most common. They depend to an extent on strain gauges, small resistors bonded to a flexible (usually metal) member. As force is put upon it, the element is slightly deformed, altering its electrical resistance within the strain gauge.

Applications: - Industrial testing machines

- Load system for cranes or lifts

- Robotics and automation systems

Advantages: - High accuracy and repeatability

- Long lifespan

- Cost-effective for large-scale industrial use

- Piezoelectric Force Sensors: Piezoelectric sensors work by using special crystals that create electric charge when they are subjected to pressure or force. The charge generated is proportional to the applied force.

Applications: - Dynamic force measurements

- Automotive crash testing

- Vibration and impact analysis

Advantages: - Great for taking rapid force measurements

- High sensitivity and frequency response

However, they are less appropriate for examining static (steady) forces since charge is lost over time. - Capacitive Force Sensors: These sensors measure changes in capacitance (the capacity to store an electric charge) between two conductive plates when a force is applied. As the plates move closer together, they cause the capacitance to change and this is measured electronically.

Applications: - Touch-sensitive devices

- Medical robotics

- Microelectromechanical systems (MEMS)

Advantages: - High accuracy for low-force measurements

- Great for the light or sensitive kettle.

- Hydraulic and Pneumatic Force Sensors: Such sensors measure force by applying fluid pressure. When force is applied, it compresses fluid in a chamber, and the pressure change is measured to determine the amount of force.

Applications: - Heavy machinery

- Automotive brakes and suspension testing

- Construction and agricultural systems

Advantages: - Can handle very large forces

- Rugged and durable

- Optical Force Sensors: Optical sensors detect deformation by observing changes in light patterns as a force is applied. These are extremely accurate and immune to electromagnetic interference.

Applications: - Precision manufacturing

- Aerospace testing

- High-end robotics

Advantages: - Excellent accuracy and noise resistance

- Suitable for sensitive environments

How do force sensors work in real-world use cases?

But let’s analyze where and how they’re actually used. You will encounter force sensing almost everywhere these days.

In Robotics

Force sensing is of enormous importance in robots for precise motion control, manipulation of objects and interaction with people. In robotic arms, torque sensors in robotics are built-in to measure the twisting force on each joint and help the robot “feel” how much pressure it is applying.

This is useful in refined tasks like electronics assembly, surgery, or handling items that are easily breakable. These tasks would be impossible to accomplish safely without the use of force sensors.

In Manufacturing

Force Sensors are used in factories to track machine stress, control press fits and maintain homogeneous product quality. For example, in the auto industry they test to see that every bolt or weld is tightened with equal force and won’t fail.

In Aerospace

Airplanes and spaceship parts are subjected to high pressures and vibrations. Force sensors can offer critical information on stress distribution, structural health, and material fatigue – and so prevent potential failures in harsh conditions.

In Healthcare

Force sensors, used in surgical robotic devices and prosthetics as well, offer feedback to help ensure precision, control and tactile sensitivity. They assist surgeons in minimizing invasiveness, and patients recover natural movement.

Factors Affecting Force Sensor Performance

The accuracy of a force sensor may be influenced by many variables:

- Temperature variances: Either a very hot or cold bead can cause the materials to expand or contract, thus changing readings.

- Electrical Noise: Signals may be corrupted by external electromagnetic interference.

- Overloading: Exceeding the force range of this sensor may lead to permanent, or excessive loss of performance over time.

- Installation and Alignment: The improper installation can result in the measurement error.

The regular calibration and maintenance ensure long-term accuracy and reliability.

The Importance of Calibration in Force Measurement

Force sensor calibration is used to verify that the force sensor reads accurately across its range. It is accomplished by loading the sensor with known weights and adjusting the output.

Advanced sensors can also drift over time without calibration, resulting in bad data and expensive production errors. A great majority of industries have very strict calibration policies, particularly in the fields of aerospace and healthcare where there is absolutely no room for error.

Force Sensors in The Age of Smart Automation

Force sensors are increasingly essential in intelligent automation as industries move towards more intelligent systems. They are the backbone of feedback-driven processes in which machines can take action based on up-to-the-minute information.

For example:

- In industrial automation robotics technology, force sensors play a role in balance maintenance and adaptive control.

- They stop accidents in collaborative robots (cobots) by feeling human touch.

- In the field of quality assurance, sensors are used to automatically check product tolerances and make a rejection decision on defect parts.

In other words, force sensors are what make automation not only faster, but smarter.

The Future of Force Sensing Tech

Miniaturization, enhanced sensitivity, and intelligent integration with IoT and AI systems represent the successful future of force sensors. Scientists are creating tiny sensors that can monitor microscopic changes in pressure that could open up new possibilities for medical devices and robotic systems.

Wireless and battery-free sensor integration is also increasing, allowing for easier deployment in harsh or mobile environments. Paired with predictive analytics, these sensors will transform performance and safety in industrial processes.

Final Thoughts

Explaining how do force sensors work isn’t just about physics, it’s also about understanding how they enable machines to sense and respond in a smart way. While from science fiction to reality, the ones who are bringing these features to life are none other than the load cells- the virtual silent warriors enabling the modern-day innovations that make human lives simpler and easier.

With the evolution of technology, there will be an increasing need for accurate, dependable and responsive force sensing. Whether you are an engineer planning automated processes or a manufacturer streamlining your premises, there is no doubt about force sensors and the central role they continue to play in the development of smart and responsive industries.