In today’s ever-changing market of the global economy, efficiency and productivity are the two pillars that determine whether a company can be at the helm of the pack or lag behind competitors. Whether factories or logistics hubs, organizations are turning towards industrial automation technology to streamline processes and remove inefficiencies in operations. Amongst all the developments in this genre, industrial automation robotics has been that one breakthrough solution which is transforming how businesses operate.

Automation is no longer just a buzzword, it has become a necessity for companies aiming to scale operations, ensure precision, and maintain consistency in output. In this blog, we’ll explore how robotics is revolutionizing the industrial automation industry, the role it plays in driving productivity, and why investing in the right industrial automation solution is key to long-term business growth.

Understanding Robotics in Industrial Automation

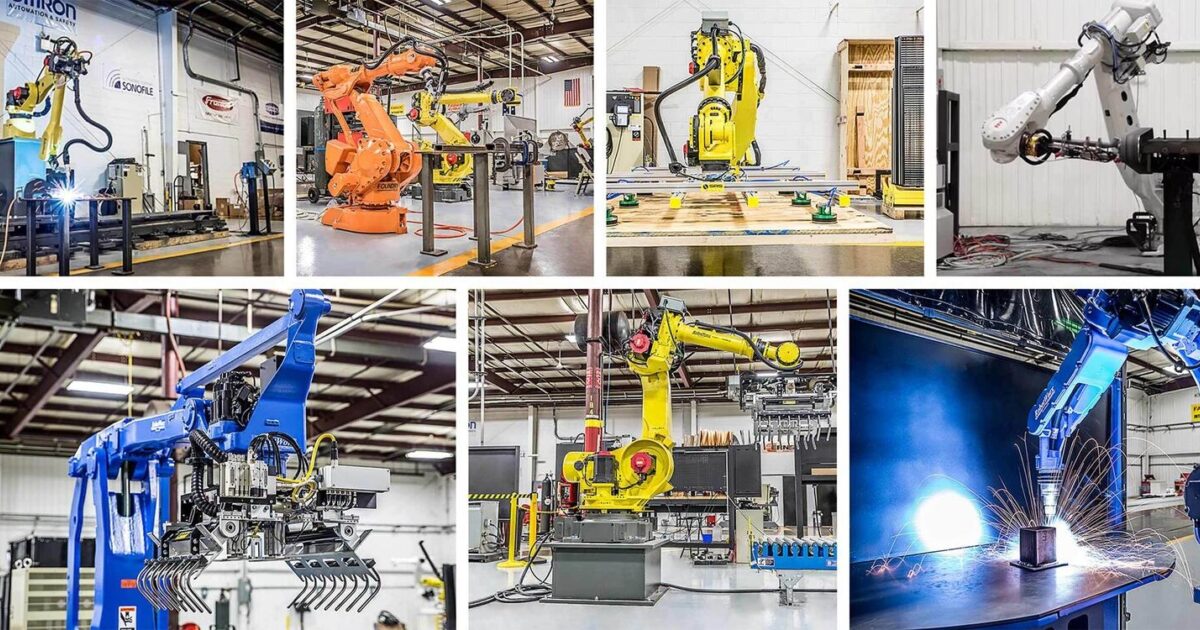

The industrial automation industry is founded on the deployment of intelligent technologies like robotics, sensors, and control systems to automate and reduce the need for human intervention in repetitive, hazardous, or precision-based processes. Robotics, for instance, brings mechanical arms, autonomous vehicles, and intelligent machines into the shop floor, reducing errors and downtime.

Unlike conventional machinery, industrial automation robotics systems are capable of learning, adapting, and executing multiple operations in one line of production. Not only does this make it more efficient, but it also offers safety and reliability in cases of high demand.

Why is Robotics Important in the Industrial Automation Sector?

Robotics used to be a luxury, but today it is a requirement in modern industrial installations. Greater need for accelerated production cycles, quality, and cost reduction has made automation inevitable. Organizations using robotics-based automation experience:

- Increased throughput with consistent product quality.

- Fewer labor-intensive positions and human errors.

- Enhanced safety at the workplace.

- Freedom to change to different lines of products with less shutdown.

As a result, robotics became the pillars of industrial automation technology to make the opportunities available for businesses to expand successfully.

Principal Benefits of Robotics in Industrial Automation

1. Increased Productivity: The major motivation for companies to invest in robotics is productivity. Robots are not prone to fatigue and therefore can work 24/7, providing constant output. They also have constant quality standards, which lower rework and wastage. In sectors such as automotive, electronics, and pharma, this consistency is vital in ensuring high-volume demand.

2. Better Safety: In sectors where hazardous chemicals, high temperatures, or heavy machinery are used, industrial automation robotics offers workers’ safety by executing dangerous tasks. It not only reduces workplace accidents but also insurance and medical costs to businesses.

3. Cost Efficiency: Although the up-front cost of robotics seems to be prohibitive, the long-term payoff is irrefutable. Automated machinery lowers labor expense, reduces downtime, and eliminates mistakes that could otherwise lead to product recalls or wasted material.

4. Consistency and Accuracy: Robots can do repetitive work more efficiently than humans, who tend to lose concentration with the passage of time. Welding auto parts, packaging consumer goods, automation ensures accuracy, uniformity, and a higher quality of output.

5. Scalability: Modern-day businesses must be agile. Robotics allows manufacturers to quickly retool production lines for new product models, staying one step ahead in competitive markets.

Role of Robotics Across Various Industries

Manufacturing: The industrial automation industry finds its most powerful application within manufacturing. Robotic arms are utilized for material handling, painting, welding, and assembly. Factories, with the presence of robots, do not only achieve higher levels of production but also attain global levels of quality.

Automotive: From the production of intricate parts to the painting of car bodies, industrial automation robotics has revolutionized the automotive industry. Robots introduce precision and efficiency that allow manufacturers to meet increasing customer expectations without compromising safety.

Logistics and Warehousing: In logistics, autonomous mobile robots are used to automate inventory management, picking orders, and moving products between warehouses. These technologies help companies fill orders faster and with fewer errors.

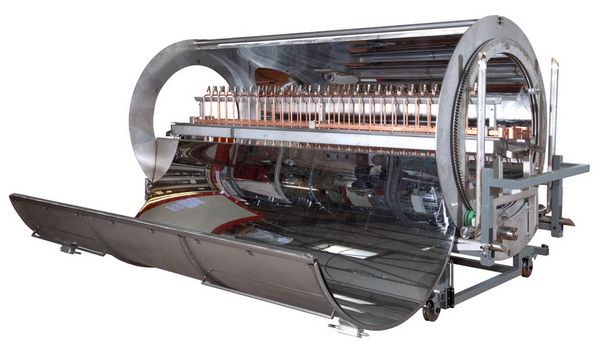

Healthcare and Pharmaceuticals: Industrial automation solutions based on precision in pharmaceutical companies ensure correct formulation of drugs, sterile packaging, and efficient supply chain management. Robotics is also becoming increasingly responsible for the handling of toxic biological substances.

Electronics: With miniaturization driving the electronics industry, industrial automation technology enables robotic units to process delicate and intricate assemblies beyond the reach of the human hand to handle consistently.

How Robotics Enhances Overall Efficiency

Efficiency is not merely a matter of speed, it is also about reducing waste, maximising availability, and optimising energy use. Robotics achieves efficiency in several ways:

- Reduced Downtime: Newer robots employ advanced predictive maintenance that eliminates surprise breakdowns.

- Energy Optimisation: Smart robotics consume less power than traditional equipment.

- Minimized Waste: Robots perform tasks with precision, reducing material waste and encouraging sustainability.

- Integration of Data: The majority of robots are IoT-enabled, allowing real-time observation and decision-making for smooth operations.

Industrial Automation Technology: The Pillar of Modern Business

Industrial automation technology growth goes hand in hand with the growth of the robotics industry. Along with hardware, automation now uses Artificial Intelligence (AI), Machine Learning (ML), and IoT for smart decision-making.

For example, AI-powered robot arms can modify their movements in real-time based on input data, ensuring zero defects. Cloud-powered systems allow remote monitoring and control, which is especially beneficial for multinational companies with global operations.

Choosing the Right Industrial Automation Solution

Different businesses don’t require the same degree of automation. The choice of the right industrial automation solution rests upon:

- Magnitude of production.

- Nature of products being produced.

- Automation budget.

- Degree of flexibility needed.

Small businesses can begin with partial automation, such as robotic assembly or packaging, while large businesses can have fully automated intelligent factories. The choice is to analyze current problems and long-term goals before investment.

Common Difficulties in Adopting Robotics

Even though the benefits are immense, businesses usually face difficulties in adopting industrial automation robotics:

- High Initial Expenses: Robots and control systems are often highly capital-intensive.

- Workforce Reskilling: Employees may need training to operate and maintain robotic systems.

- System Integration: Aligning new robotics with existing legacy systems may be complex.

- Maintenance Requirements: Advanced robots require regular servicing to avoid downtime.

Despite these challenges, the long-term advantages far outweigh the barriers, making robotics adoption a strategic move.

Best Practices for Maximising ROI from Robotics

To reap the true benefits of robotics in automation, companies must:

- Invest in training personnel.

- Update and maintain systems frequently.

- Attack critical areas first before applying to all processes.

- Use data analysis to monitor performance and optimize operations.

- Partner with trusted industrial automation solution providers who offer after-sales support.

Future of Robotics in the Industrial Automation Industry

The future of the industrial automation industry is inter-connected with the growth of robotics. Following are some trends which organizations can anticipate:

- Collaborative Robots (Cobots): To work alongside humans, cobots enhance flexibility and reduce labour stress.

- AI-Driven Robotics: Robots with decision-making capabilities to optimize processes in real-time.

- Green Automation: Green robotics to empower sustainability programs.

- Hyper-Automation: Integrating robotics with AI, IoT, and machine learning for automated processes end-to-end.

- Cloud Robotics: Remote monitoring and control using cloud-based platforms.

These trends will establish robotics as a top player in the field of industrial automation technology.

Conclusion

Robotics is no longer an impending promise but the existing reality. From production to healthcare, logistics to electronics, industrial automation robotics is setting new benchmarks for productivity, safety, and efficiency. Organizations embracing these technologies place themselves in a position not only to manage current market requirements but also to transform rapidly in order to address future demands.

The automation industry is racing at breakneck velocity, and robotics is its center of action. By adopting the right industrial automation solution, companies can cut costs, improve quality, improve safety, and enhance total output.

In short, automation is not about replacing individuals, it’s about enabling businesses to accomplish more for less. And in a time when productivity is equal to success, robotics is a life-altering development across industries worldwide.